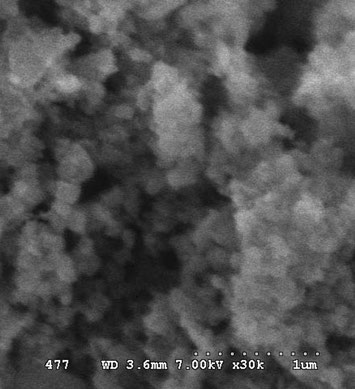

Hexagonal Boron Nitride Powder

Hexagonal BN is formulated from ceramic. One of the common forms of polymorphism is hexagonal BN. Not only it lubricates at low but even at high temperatures and in an oxidising environment it can be as high as 900 degrees Celsius. The chemical reactivity or electrical conductivity of a different form of lubricant may turn out to be a concern, but H- BN turns out to be handy on all counts.

The major benefit of hexagonal boron nitride powder is that the lubricant is not dependent on gas molecules or trapped water. For this reason, it is being employed in a vacuum environment like a space application. H- BN components that are fine-grained would be utilized in dental elements, pencil leads or cosmetics due to the lubricant characteristics on offer.

A review of the history of hexagonal boron nitride powder

It was around the year 1940, hexagonal boron nitride powder was used as a cosmetics product in Japan. But the idea was abandoned when it came to the application due to excessive cost. Towards the later part of the 1990s, there was an optimization of the H- BN production methods it had a form of reinvention. Presently it is being employed by all cosmetic companies due to the features of make-up, lipsticks, kohl pencils, blushers or be it skincare items.

For a considerable period of time, it has been put to use in the form of high-temperature equipment. The main reason for the user exists in the form of thermal or chemical stability. With H- BN it is all about incorporating self-lubricating properties, into plastics, resins, ceramics or any form of metals. The materials are reliant to be used in the manufacturing of steel and bearings.

BN-incorporated particles are known to showcase a lower level of thermal expansion with electrical conductivity on the lower side. It is subject to being used in the form of a substrate for windows that are micro–transparent, semiconductors or it can be in the form of a structural material when it comes to sealing. It is all due to thermal and dielectric properties.

When it comes to hexagonal boron nitride powder, it is subject to be utilized as a leakage barrier of the photo drum in laser printings and xerographic processes. This is available in the form of a binder that is being used in the automotive sector for sealing oxygen sensors. This is going to provide input when it comes to changing the fuel flow.

The binder would cash in on the thermal stability along with insulating properties. Being an abrasive substance. Cubic boron oxide is being used at an extensive level at the same time.